The Process of Making Wood or Biomass Pellets

It's worth noting that in order to make pellets, you need specialized equipment. And while it may be possible to build a homemade pellet mill, I haven't seen a reliable productive one in action yet. If in fact you know of one, feel free to leave a comment with a link to it. That said, There are two main requirements, the raw material, and the equipment to make the pellets.

The Material

You can make wood or biomass pellets out of many different materials. Both softwood and hardwood are both used and produce excellent results. What's really interesting though is that it's also possible to make biomass pellets out of a wide variety of materials. Some of the possible ingredients are - switch grass, grain, corn cobs, corn stalks, paper, sawdust, distiller grain, and many others. There are many potential materials that can be used with good results. The common rule of thumb is that if you can reduce the size of your chosen biomass into granular form, you can make pellets from it.

The Equipment

There are several pieces of equipment that are used in the commercial wood pellet manufacturing process. These can include hammer mills, dryers, pelletizers, coolers, baggers, and boilers to name a few of the major ones. Note that this is for a large scale commercial manufacturing pellet line. If you're making pellets on a smaller home use scale, It's possible to get by without all of these. Typically, home made wood or biomass pellets are made in a small scale pellet mill. Depending on how large the size of the raw material is, you may also need to use a small hammer mill. The goal is to make the particles smaller than 1/4". If your raw material is smaller than 1/4" to begin with, when using sawdust for instance, you won't need a hammer mill.

The Process

As they say, the devil is in the details. Depending on what your raw materials are, i.e. switch grass versus sawdust for instance, the "recipe" will change. We'll use dried wood as the raw material for the example that follows.

First, if the raw material is larger than 1/4", it's broken down in the hammer mill to a smaller particle size. Next, the raw fiber is either put into the pelletizer and heated with steam, pressure, a combination of both. This causes the naturally occurring lignin to plasticize and hold the pellet together after it passes through the pelletizer and cools down.

Make Wood Pellets

Lignin is a natural substance that's found in wood and acts like glue. If your raw material isn't wood and doesn't have lignin, a different binding agent will need to be added to hold the pellets together. This binder will depend on what particular raw stock you are using. Some of the commonly used binders are vegetable oil, clay, starch, cooking oil, or wax to name a few.

In the pelletizer, the raw material is routed through a die and rollers. The rollers force the material through a die that gives the pellets their characteristic tubular shape. Once they exit the pelletizer, they are then allowed to cool down. This causes the pellets to harden, and allows them to retain their shape.

Finally, the pellets must be allowed to dry out. A moisture content of from 5% - 15% should be adequate. The exact percentage will depend on the raw material that you're using to make your pellets.

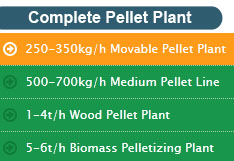

Complete Wood Pellet Mills

Small Mobile Pellet Plant

Biomass Pelletizing Plant

Drum Chipper

Wood & Straw Crusher

Hammermills

Heat Stove

Rotary Drum Dryers

Ring Die Pellet Mill

Pellet Mill With Ring Die

Flat Die Pellet Mill

Spare Parts Dies & Rollers

Steam Boiler

Cooler

Pellet Packing Machine

PLC Control for Pellet Mill

Conveyor

Pellet Pulse Dust Collector

Magnetic Separator

Pellet Stove Fireplace

Small Pellet Mill

Spanish

Spanish French

French Russian

Russian