Pellet HammerMills, Feed Hammermills

(1)Crush raw materials such as corn,cotton seeds waste,bean waste.95% of the raw materials can get through 60 meshes, no block.

(1)Crush raw materials such as corn,cotton seeds waste,bean waste.95% of the raw materials can get through 60 meshes, no block.

(2)The efficiency of the production is top-A in the world.When the screen vibrates,the efficiency could be increased by 20-300%.According to the experiment,use 75Kw to the vibrate hammer mill,5.5Kw to theimpulse fan ,1.2mm in diameter of the mesh,

the capacity of crushing corn is 6 t/h.Degree of fineness:98% get through 24 meshes(0.85mm),80% get through 65 meshes,49% get through 80 meshes.![]()

(3)Auxiliary facilities are as simple as the ordinary water drip hammer mill.The power doesn’t increase. So it’s very easy to update the old machine.

(4)The machine is stable and reliable.Vibrator,elastomer,screen can be replaced outside the machine.

Model |

SFSPZ7 0 × 75 |

SFSPZ112 × 75 |

SFSPZ130 × 75 |

Power(KW) |

75/90 |

110/132 |

160/200 |

Copachy(t/h) |

5.5-6.5 |

8-10 |

11-15 |

SWFL Super Micron Mills

1, A vertical-screen smash, compact, small footprint;

1, A vertical-screen smash, compact, small footprint;

2, Ginding and classification at the same body can be crushed at the same time, grading, thenit is the process of smashing, finished granularity reaches 60 to 200 mesh, uniform size;

3, The classification system optimization design, grading high efficiency;

4, The observation of the door structure, and easy to maintain;

5, With th optional hydraulic opening, the body can quickly smash open the room to facilitate maintenance or replacement;

6, Equipped with a variety of sensors, more reliable equipment operation;

7, With special muffler, the noise can be significantly reduced.

8, The unique breaking arch feeding device to prevent feed materials at the end arch;

9, Can be used in corn, wheat, fish meal, Shell, defatted soy, monosodium glutamate, glucose, pharmaceuticals, dyes intermediates, activated carbon, and other materials AMD smash

Model |

SWFL82B |

SWFL110B |

SWFL130B |

Capacity |

1.2-2.2 |

1.8-3.0 |

3.0-5.5 |

Main Motor Power(kw) |

90 |

110 |

132/160 |

Rotor Diamete(mm) |

820 |

1100 |

1300 |

Grading Motor Power(kw) |

5.5 |

7.5 |

11 |

Water Drip Figure Pellet Hammermills

(1)Adopting the modern international technic,crush room is designed to be water drip figure.The secondary crushing can increase output by 25%. Adjustable hammer-screen space can optimize hammers’ arrangement.The mill can work as ordinary crusher and miro crusher.

(1)Adopting the modern international technic,crush room is designed to be water drip figure.The secondary crushing can increase output by 25%. Adjustable hammer-screen space can optimize hammers’ arrangement.The mill can work as ordinary crusher and miro crusher.

(2)Full open operating door;coordinated screen fixing device;easy to replace and repair screen

(3)Safe and environmental: inlaid airproof avoids the dust from overfall thoroughly.

(4)Been tested by precise balancing apparatus,then the hammer mill willkeep quiet when it is running. This reduces noise and protracts the bearing’s life.

(5)The crusher is widely used in feed factories to produce poultry feed,aquatic feed;also in alcohol plants,citric acid plants,food product factories to crush pellet material.

Model |

999-1 |

999-2 |

999-3 |

Power(kw) |

75/90 |

110/132 |

160/200 |

Copachy |

12~15 |

25~35 |

38~50 |

Small Water Drip Figure Pellet Hammermills

More humanized operate design,strengthen safe and environmental degree.Coodinated screen fixing device is developed with the most advanced technic.Real water drip figured crush room.

Model |

SFSPZ7 0 × 75 |

SFSPZ112 × 75 |

SFSPZ130 × 75 |

Power(KW) |

75/90 |

110/132 |

160/200 |

Copachy(t/h) |

5.5-6.5 |

8-10 |

11-15 |

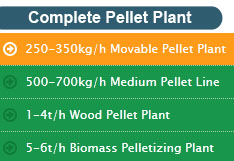

Complete Wood Pellet Mills

Small Mobile Pellet Plant

Biomass Pelletizing Plant

Drum Chipper

Wood & Straw Crusher

Hammermills

Heat Stove

Rotary Drum Dryers

Ring Die Pellet Mill

Pellet Mill With Ring Die

Flat Die Pellet Mill

Spare Parts Dies & Rollers

Steam Boiler

Cooler

Pellet Packing Machine

PLC Control for Pellet Mill

Conveyor

Pellet Pulse Dust Collector

Magnetic Separator

Pellet Stove Fireplace

Small Pellet Mill

Spanish

Spanish French

French Russian

Russian