Wood Powder Mill

Wood powder mill has fine technics, highly Processing technology, double the body, infuse water supply in the body and has water-cool effect, into a new type of material, has sound insulation, disperse effect. And wood powder mill has small noise and nothing libration in processing.

Woodworker wood powder mill has Beautiful appearance, rugged, high-yield, and efficiency higher about than traditional wood powder mill. It is perfect wood powder mill, and any crusing machines couldn’t instead in wood powder mill.

The Wood Powder Mill: wood powder, wood brand, bamboo powder, skin chestnut powder, flour Elm, wood grain, wood, paper tablets, camphor wood powder, cedar powder, dried small shrimps powder, star anise powder, pepper, chili powder, pepper, refined cotton, Feathers, plume stems, rice straw, wheat bran, rice husk, wood stick, ballast potato, cassava, Chinese herbal medicine, fish meal, Bing Lei, Sanshui, such as magnesium silicate and fibers of all types of materials processing to crush.

Wood powder mill is indispensable wood crushing machine, example: bakelite, plastic, paper making, welding rod, mosquito coil incense, sanitation coil incense, fireworks, firecracker, feed, herbal medicine, detonator, breed quatics and so on. Wood Powder Mill: contain crude crushing, refined crushing, wind powder feeding and so on.

Due to the electromotor driver run up of principal axis, so that wood powder mill be able to bring high intense impinge, cut down, incise, friction, to the raw material be crushed. And wood powder mill has one idiographic function about fibrous material can be crushed.

The structure of wood powder mill and comminute elements:

1/the wood powder mill contain three parties: mainframe, Middle enginery and belowe enginery

2/comminute knife had seven type knife, line type knife and centrifugal knife.

3/assistant enginery make up of Air fan, powder collecter and dust catcher.

4/mainly enginery adopt seven type knife, line type knife and certrifugal knife, has crude crushing, refined crushing and sentrifugal crushing again. And due to the electricity drive the pulverizer’s rotor to run up. And using the enginery bring high speed airflow to come into being highly intense impinge, cut down, incise, friction, to the raw material be crushed

5/at incise course of three types knife: The rotor bring high speed airflow to circumgyrate follow knife, the material be accelerated and repeat impact, incise friction in airflow, and feeling three types of comminution, the material be crushed to analysis by analyzer follow airflow, due to the material be crushed from centrifugal force of the analyzer’s rotor and airflow’s centripetal force, so when the centrifugal force than centripetal force, granule put into power of collecter, and thick put into crushing room and continue crushing until you satisfy the size.

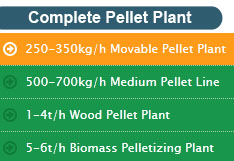

Complete Wood Pellet Mills

Small Mobile Pellet Plant

Biomass Pelletizing Plant

Drum Chipper

Wood & Straw Crusher

Hammermills

Heat Stove

Rotary Drum Dryers

Ring Die Pellet Mill

Pellet Mill With Ring Die

Flat Die Pellet Mill

Spare Parts Dies & Rollers

Steam Boiler

Cooler

Pellet Packing Machine

PLC Control for Pellet Mill

Conveyor

Pellet Pulse Dust Collector

Magnetic Separator

Pellet Stove Fireplace

Small Pellet Mill

Spanish

Spanish French

French Russian

Russian